advertisement

Brand Information

3A Composites GmbH has developed manufactured and marketed high-quality aluminum composite panels, structural composite material, plastic sheets and lightweight foam boards for architecture, visual communication and transport & industry markets since 1969. The company’s famous brands ALUCOBOND®, DIBOND®, ALUCORE®, KAPA® and FOREX®, have established its reputation as a global company.

Following the integration of the Polycasa group in April 2015, 3A Composites GmbH has extended its product portfolio with a wide choice of plastic sheet to strengthen its position as a diverse and leading manufacturer of materials for display, building and industrial applications in Europe.

3A Composites GmbH is part of the international 3A Composites Group. The group belongs to the listed company Schweiter Technologies headquartered in Steinhausen, Switzerland. 3A Composites, formerly known as Alcan Composites, is an independent division of Schweiter Technologies since December 1st, 2009 and has approximately 4300 employees worldwide. In addition to the above mentioned market segments, 3A Composites focuses on wind energy and the marine market with their trademarks AIREX® and BALTEK®.

HISTORY

- 1956 Airex AG founded in Sins, Aargau by Lonza

- 1969 Development of KAPA® and ALUCOBOND®

- 1980 Development of FOREX®

- 1990 alusuisse composites is founded

- 1992 DIBOND® is launched in Singen

- 1994 Plant expansion for the production of ALUCORE®

- 2000 Alcan takes over Alusuisse

- 2006 Development of SMART-X®

- 2007 RioTinto takes over Alcan | HYLITE® is launched

- 2009 Schweiter Technologies takes over Alcan Composites

- 2010 Alcan Composites becomes 3A Composites

- 2012 3A Composites takes over Foamalite

- 2015 3A Composites takes over Polycasa | DISPA® is launched

- 2017 3A Composites takes over Athlone Extrusions

- 2019 3A Composites takes over Perspex International Ltd.

OUR PRODUCTS

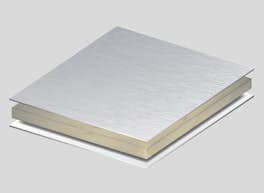

The product. High-quality, resilient and unique in appearance – ALUCOBOND® stands for sustainable construction quality and the highest creative standards. The façade material is distinguished by its outstanding product attributes such as precise flatness, variety of surfaces and colours as well as excellent formability.

ALUCOBOND® is produced with various core thicknesses in a continuous lamination process and cut to format. All painted panels are supplied with a protective peel-off foil.

ALUCOBOND® PLUS

The aluminium composite panel with a fire-retardant mineral filled core

ALUCOBOND® A2

The aluminium composite panel with a non-combustible high-filled mineral core

ALUCORE®

The extremly lightweight aluminium honeycomb panel

Canary Wharf Crossrail, London, UK | Architect: Adamson Associates | © Richard Gooding

FIRE SAFETY

When planning a building, the topic of fire protection is as essential as that of statics. It is like the “airbag” of a building – perhaps not always noticeable at first glance, but one has to be able to rely on it in case of emergency. If possible, it should never impair the aesthetics of good architecture.

CONSTRUCTION

ALUCOBOND® convinces with a multitude of simple processing and installation options. The material can be sawn, milled, folded and bent using the standard tools of metal and façade builders. It can either be riveted or screwed on to the substructure, or else installed as a suspended cassette. On top of this, the aluminium composite panel is available in flame-retardant and non-combustible versions to meet the building's fire safety requirements of the respective country.

Casa Invisibile, Slovenia | Architect: DMAA | © Christian Brandstätter

SUSTAINABILITY

We have been committed to the environment and future generations for decades. Our goal is to meet the most stringent economic, social and ecological demands. ALUCOBOND® composite panels do not release environmentally hazardous substances at any point in their life cycle. After many years of use, they remain fully recyclable and can be returned to the material cycle. The requirements of current energy guidelines can easily be met with ALUCOBOND® and a rear-ventilated façade.

EXPERIENCE

The development of ALUCOBOND® more than fifty years ago was a small revolution in itself: an innovative type of aluminium composite as a material compound that was light, rigid, very easy to form, and even corrosion-resistant and recyclable. These extraordinary characteristics convinced architects, designers and builders not only then but even now.

Find this Brand from these Suppliers

Looking for new opportunities in the Saudi market?

Receiving real RFQs is the key for new orders.

Here in Project Suppliers platform we gain you the new opportunity.